Cerakote

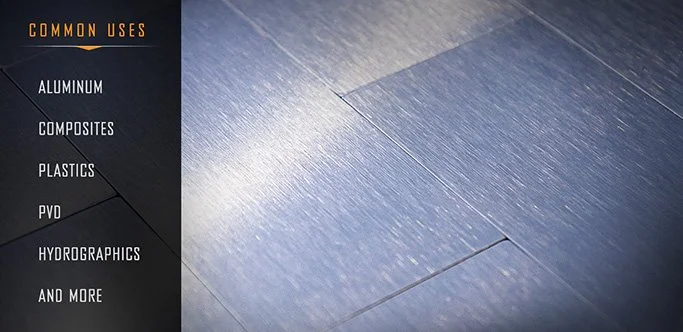

Cerakote is an inorganic, thin-film ceramic based coating with Unique and desirable performance traits engineered in. ideal for a wide variety of applications, it balances durability with the availability of a wide gamut of colours.

Cerakote offers outstanding chemical and corrosion resistance compared to coatings such as nitriding, DLC and blueing. Certain series of Cerakote can withstand temperatures up to 1800°F without discolouring or failing. This coating is applied at a thickness of 0.001-0.003” which make it great for high tolerance areas.

Available in over 200 unique colours. This product can be applied on to metals, polymers and wood.

The Process

-

Parts are taken down to their most basic form. This ensures maximum coverage of Cerakote and promotes efficiency for the next step, DSG.

-

“DSG” is an internal term for degrease, sandblast, and gas out. This process is done to promote the best adhesion and performance of the Cerakote. It involves removing the existing coating on the part, remove grease and oils on the surface as well as within the substrate, and embedding the ideal blasting profile for Cerakote.

-

Cerakote is then applied as a wet coating onto the part. Each coat is sprayed with precision for full coverage, uniform coating thickness, and uniform surface finish.

-

Most Cerakote colours require a curing process at a high temperature. This is done in a laboratory grade oven to reduce differences in curing temperatures within the oven.

-

Coating is checked over for quality. Parts are reassembled. All applicable functions are checked before returning to the customer.

Performance Finishes

“H” and “E” series

The jack of all trades. This series offers great corrosion and chemical resistance with a thin coating thickness. Available in a large gamut of colours this Cerakote series is ideal for most situations.

“V” and “C” Series

In certain applications where high temperatures are a major concern, this series is the right choice. A small amount of corrosion resistance is the trade off for better UV and thermal stability. Automotive exhausts are a common use case for this series.

Performance Clears and SPecialty Coatings

If there are other specific requirements you need from your coating, Cerakote most likely has a product that meets those requirements. Products from dielectric coating to textured coating to aluminum specific clears. The possibilities are endless.

IT IS ALL IN THE DETAILS

Certain projects require specific surfaces preserved for various reasons like preserving tolerances. Our technicians can mask these areas to ensure the end product functions as intended.

Extensive preparation

Parts are thoroughly cleaned and degreased to ensure that there is no external contamination on the surface of the items. Prepared items will then be masked and sandblasted to achieve a sufficient etch profile to which the Cerakote will adhere. Following sandblasting the parts will then be baked in an oven to remove any remaining moisture and oils. Once the items are ready to be sprayed they go for a final inspection. Following spraying with Cerakote, coated parts are returned to the oven for a final and full bake to cure the coating